学术前沿

-

A Markerless AR Guidance Method for Large-Scale Wire and Cable Laying of Electromechanical Products

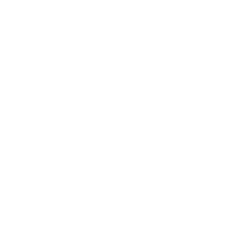

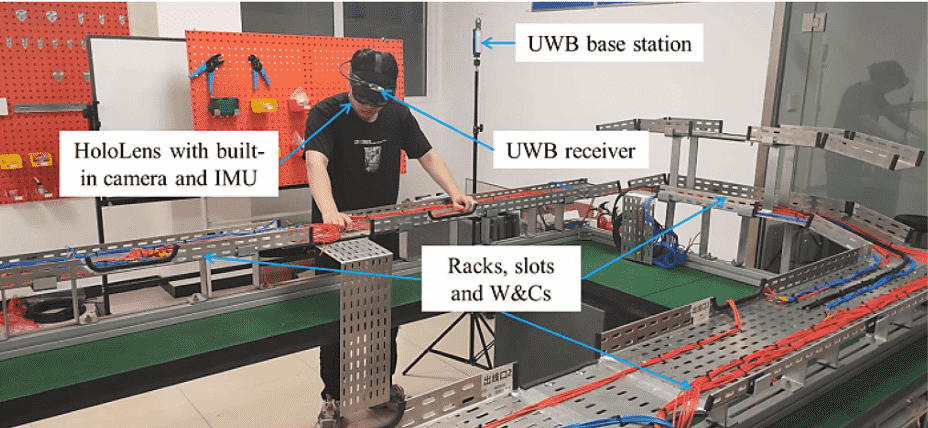

Abstract: Large-scale wires and cables (W&Cs) are the nerves of large and complex electromechanical products vital to their regular operation. The laying process of W&C has been highly dependent on manual work and urgently needs intelligent guidance like augmented reality (AR). However, model registration and occlusion handling based on AR for large-scale W&C laying scenes cannot achieve high-quality results to date because of the lack of texture, the local field of vision, and other characteristics. Therefore, a markerless AR guidance method for large-scale W&C laying is proposed to address this long-lasting problem. First, camera, ultrawideband, and inertial measurement unit sensors are integrated to coarsely register the W&C models based on coordinate transformation and mapping virtual and physical spaces. Then, a local edge matching method is used to register the W&C models based on the coarse one finely. Next, the occlusion relationships of the W&C models are handled based on assembly constraints; the models are anchored in the simultaneous localization and mapping map for visual and continuous guidance. A locomotive W&C laying case study and evaluation results show that this method meets industrial application requirements regarding efficiency, accuracy, and robustness and has several advantages compared to other methods, including extra-large scale, automatic registration, and virtual-real fusion.

Author: Geng, Junhao; Chen, Mengbo; Zhao, Xinyang; Liu, Yu; Ma, Yongsheng

-

飞机装配作业AR智能引导技术探索与实践

摘要:为解决增强现实应用系统在通用性、一体化方面的不适应性,以满足飞机装配中的实际应用需求,提出一种新的飞机装配作业AR智能引导系统。首先,开展了基于动态操作描述的通用化AR装配指令和基于连续作业状态的一体化操作引导两项关键技术研究;其次,构建了面向飞机装配作业的AR智能引导系统;最后,该系统在实验室环境中,进行了飞机液压系统管路装配应用实践。初步实现了在液压管路装配过程的实时引导和装配结果的智能检查。

作者:唐健钧; 叶波; 耿俊浩

-

Exploring the synergies between collaborative robotics, digital twins, augmentation, and industry 5.0 for smart manufacturing: A state-of-the-art review

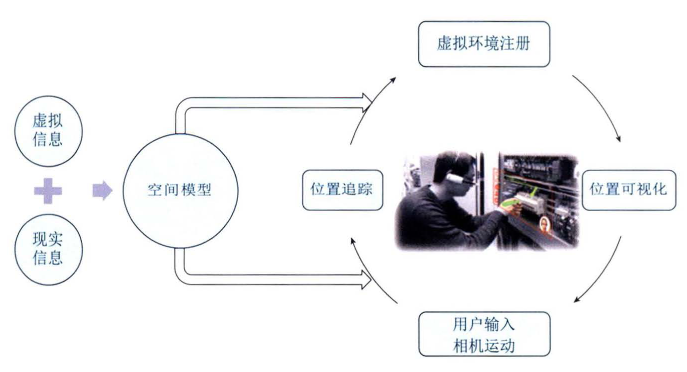

Abstract: Industry 5.0 aims at establishing an inclusive, smart and sustainable production process that encourages human creativity and expertise by leveraging enhanced automation and machine intelligence. Collaborative robotics, or "cobotics",is a major enabling technology of Industry 5.0, which aspires at improving human dexterity by elevating robots to extensions of human capabilities and, ultimately, even as team members. A pivotal element that has the potential to operate as an interface for the teaming aspiration of Industry 5.0 is the adoption of novel technologies such as virtual reality (VR), augmented reality (AR), mixed reality (MR) and haptics, together known as "augmentation". Industry 5.0 also benefit from Digital Twins (DTs), which are digital representations of a physical assets that serves as their counterpart - or twins. Another essential component of Industry 5.0 is artificial intelligence (AI), which has the potential to create a more intelligent and efficient manufacturing process. In this study, a systematic review of the state of the art is presented to explore the synergies between cobots, DTs, augmentation, and Industry 5.0 for smart manufacturing. To the best of the author's knowledge, this is the first attempt in the literature to provide a comprehensive review of the synergies between the various components of Industry 5.0. This work aims at increasing the global efforts to realize the large variety of application possibilities offered by Industry 5.0 and to provide an up-to-date reference as a stepping-stone for new research and development within this field.

Author: Zafar, Muhammad Hamza; Langas, Even Falkenberg;Sanfilippo, Filippo

-

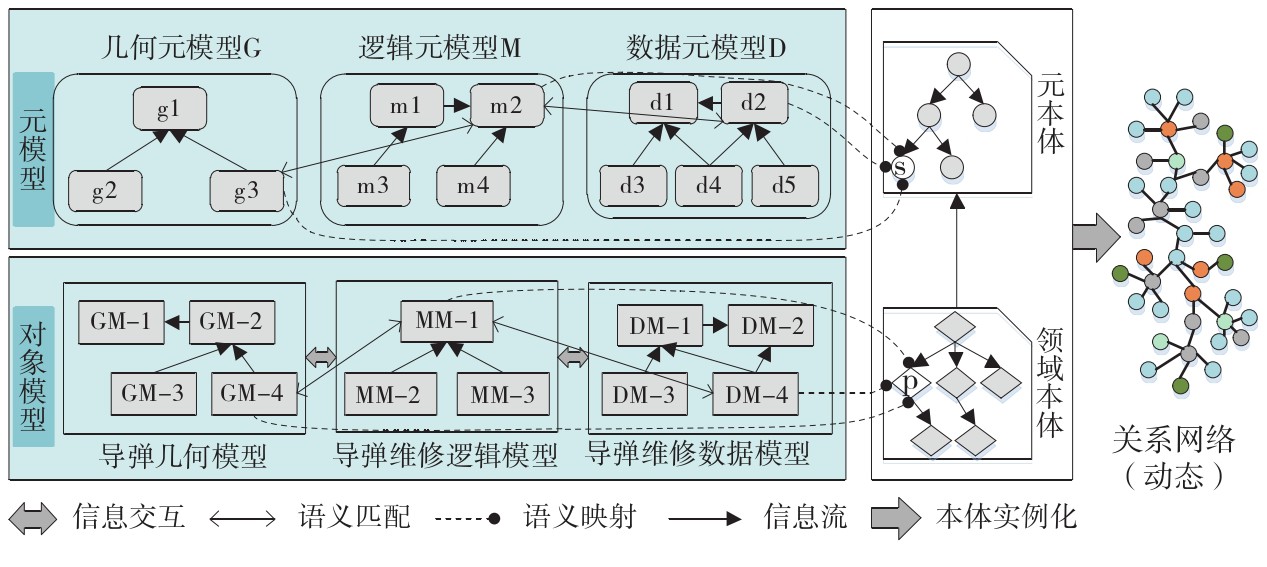

增强现实与数字孪生混合驱动的航天复杂装备

维修辅助技术研究摘要: 针对未来信息化战争条件下航天复杂装备维修保障面临的型号种类多、模块可视化程度低、战时保障前后端衔接不足、人员训练量化评估考核手段缺乏、维修大数据难以挖掘和复用等瓶颈问题,以典型武器装备为对象,提出一种基于增强现实技术、数字孪生内核驱动的维修保障与人员训练系统框架,阐述了数字孪生模型构建、故障在线诊断、维修流程诱导、人员动态评估等关键环节的技术途径,论述了航天复杂装备辅助维修系统的开发与集成要点并展示了原型系统,为实现靠前保障、快速保障提供了可行的技术路径。

作者: 钟珂珂; 洪海波; 宋倩; 郭宇; 魏士松

Industry Trends

-

NASA Uses AR Technology for Remote Maintenance of ISS Experimental Equipment

Recently, NASA astronauts have applied the HoloLens AR headset to many scenarios on the International Space Station. In addition to the previously announced treadmill maintenance, it has also been used recently to maintain the Cold Atom Laboratory. It is reported that this is the first time astronauts have used AR assistance to repair scientific experimental equipment. In the future, this technology is expected to be used for remote upgrades of the Cold Atom Laboratory, eliminating the need to transport it back to Earth.

-

Forecast 2024: Outlook on Virtual/Augmented Reality (VR/AR) Industry Technology Trends (Including Technical Paths, Investment Directions, Patent Landscape, and Technology Company Layouts) - Industry Research Report - Qianzhan Market Research

Virtual reality (VR) is a computer simulation system that allows for the creation and experience of virtual worlds, while augmented reality (AR) technology is a technique that skillfully integrates virtual information with the real world. Generated virtual information such as text, images, 3D models, music, videos, etc., are simulated and applied to the real world, with the two types of information complementing each other, thus "enhancing" the real world.

-

Second-generation Augmented Reality (AR) Head-mounted Display Devices _ VR devices _ What's Worth Buying

HoloLens 2 is the second-generation augmented reality (AR) head-mounted display device developed by Microsoft, designed to provide users with a more immersive virtual reality experience. Here is a detailed introduction to HoloLens 2:

Ⅰ. Product Features

1. Design: HoloLens 2 features a carbon fiber body, designed for enhanced comfort, with additional padding for long-term wear.

2. Processor: Equipped with the Qualcomm Snapdragon 850 processor internally, providing better performance support

3. Display technology: An optical display solution utilizing laser beam scanning (LBS) is employed, combined with waveguide technology, achieving a wider display viewing angle and higher display brightness.

4. Sensors: Equipped with various sensors such as hand tracking, eye tracking, and voice commands, providing a rich array of interaction methods.

5. Functions: It supports spatial mapping, mixed reality capture, 6DoF tracking, and other functions, providing users with a more realistic virtual reality experience. -

Hisense Jukangzhan Showcased at the Virtual Reality Innovation Conference How AI+XR Drives the Digital Transformation of the Manufacturing Industry - Technology, Enterprise, and Training

To promote new industrialization and accelerate the construction of a powerful manufacturing nation, more and more enterprises are focusing on virtual reality technology as a key aspect of industrial digital transformation. On November 12th, the 2024 International Virtual Reality Innovation Conference opened in Qingdao. Hisense Jukangxian showcased its latest industrial metaverse solution, demonstrating the new progress of AI+XR empowering industrial digitalization, attracting many participants to stop and experience.