Intelligent Design and Simulation of Rigid-flex Hybrid EWIS Assembly Prototype

EWIS assembly design has emerged as a bottleneck hindering the research and development of electromechanical equipment, including aircraft, rockets, and locomotives. The project team has pioneered the development of an autonomous and controllable industrial software, specifically designed for EWIS rigid-flex hybrid environments, with a particular focus on lightweight modeling and simulation of flexible wiring harnesses. The software's core technology has initially enabled large-scale, cross-scale collaborative geometric and physical modeling (encompassing geometric dimensions, spatial arrangements, motion deformations, etc.) as well as collaborative simulations of various behaviors (such as gravity-induced deformations, impact vibrations, collision interferences, etc.) of flexible wiring harnesses, relying entirely on network databases, positional dynamics, and multigrid techniques. Additionally, it can seamlessly integrate wiring harness assembly models exported from electrical CAD systems like CATIA, NX, and CHS, accurately estimating the actual laying length through simulation and achieving a 23.9% reduction in cable material usage.

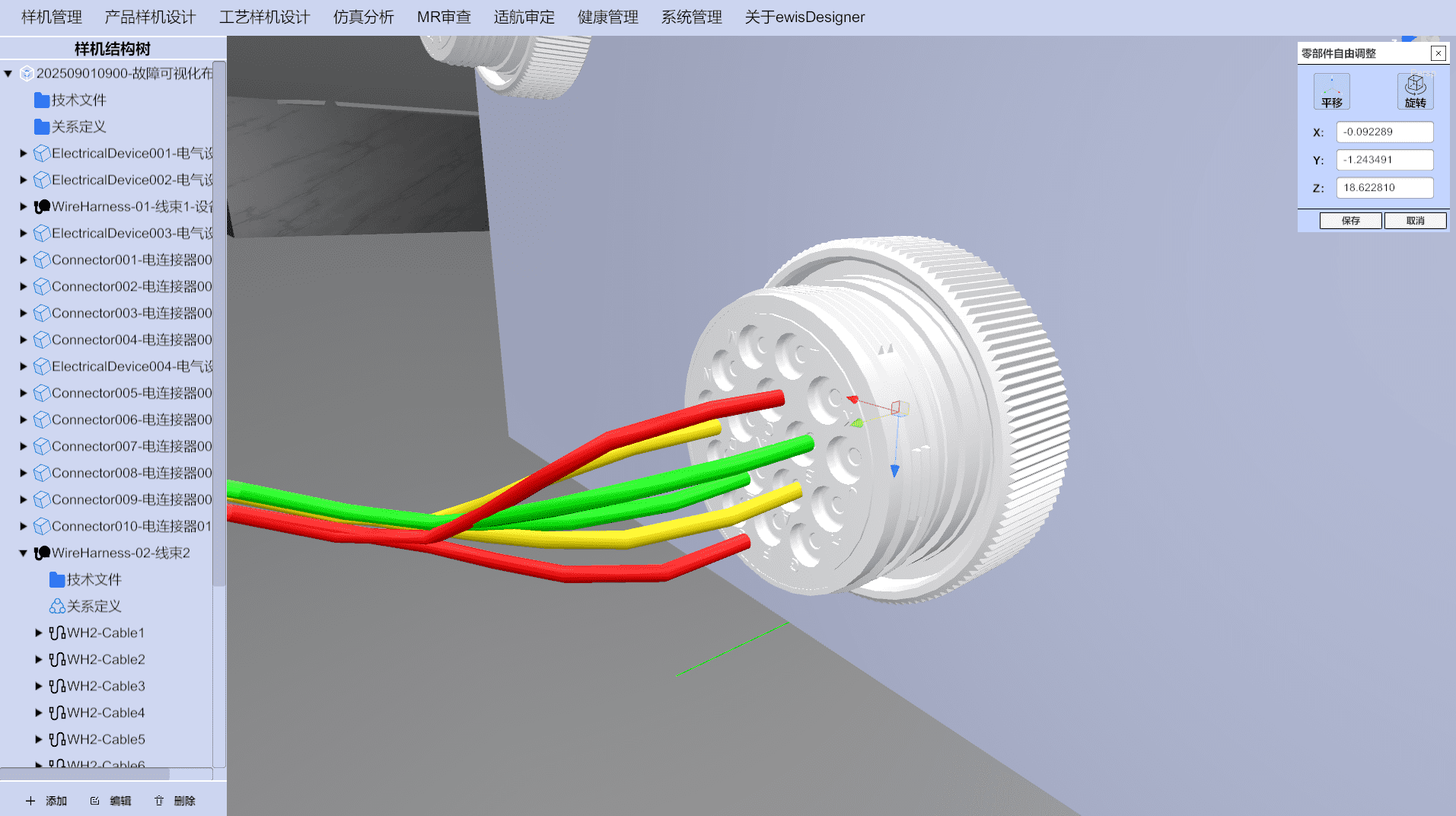

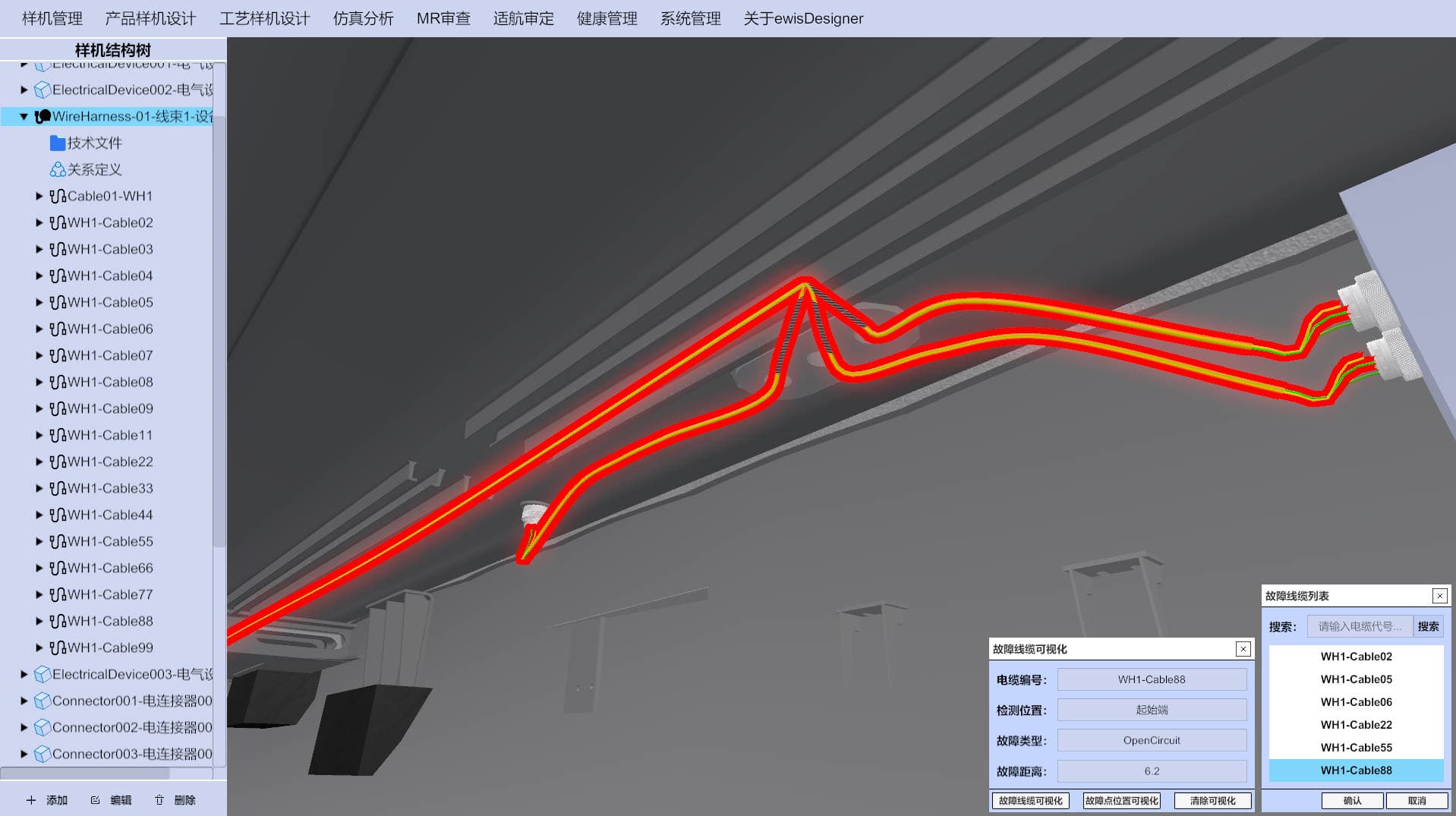

Intelligent Compliance Analysis and Health Management of Complex Equipment EWIS

The evaluation of EWIS wiring harness performance indicators serves as the foundational work for analyzing the conformity of complex equipment wiring harness manufacturing. The project team has successfully developed a pioneering software module tailored for EWIS wiring harness form conformity analysis and health management. This innovative module employs a wiring harness assembly prototype as its operational platform, leveraging simulation data to meticulously analyze critical performance metrics including harness routing, bending characteristics, interference potential, and separation requirements. By integrating manufacturing conformity considerations into the design phase, the module enables a precise assessment of assembly design maturity, thereby minimizing material waste, reducing the likelihood of design modifications, avoiding production rework, and ensuring product quality stability to safeguard equipment integrity. In the operational maintenance phase, the module utilizes predefined electrical connection logic models and wiring harness assembly topology models to facilitate fault cause analysis and correlation impact assessment. This capability enables rapid, intelligent, and visual fault localization for wiring harnesses and associated connection devices, thereby providing robust support for comprehensive EWIS health management.

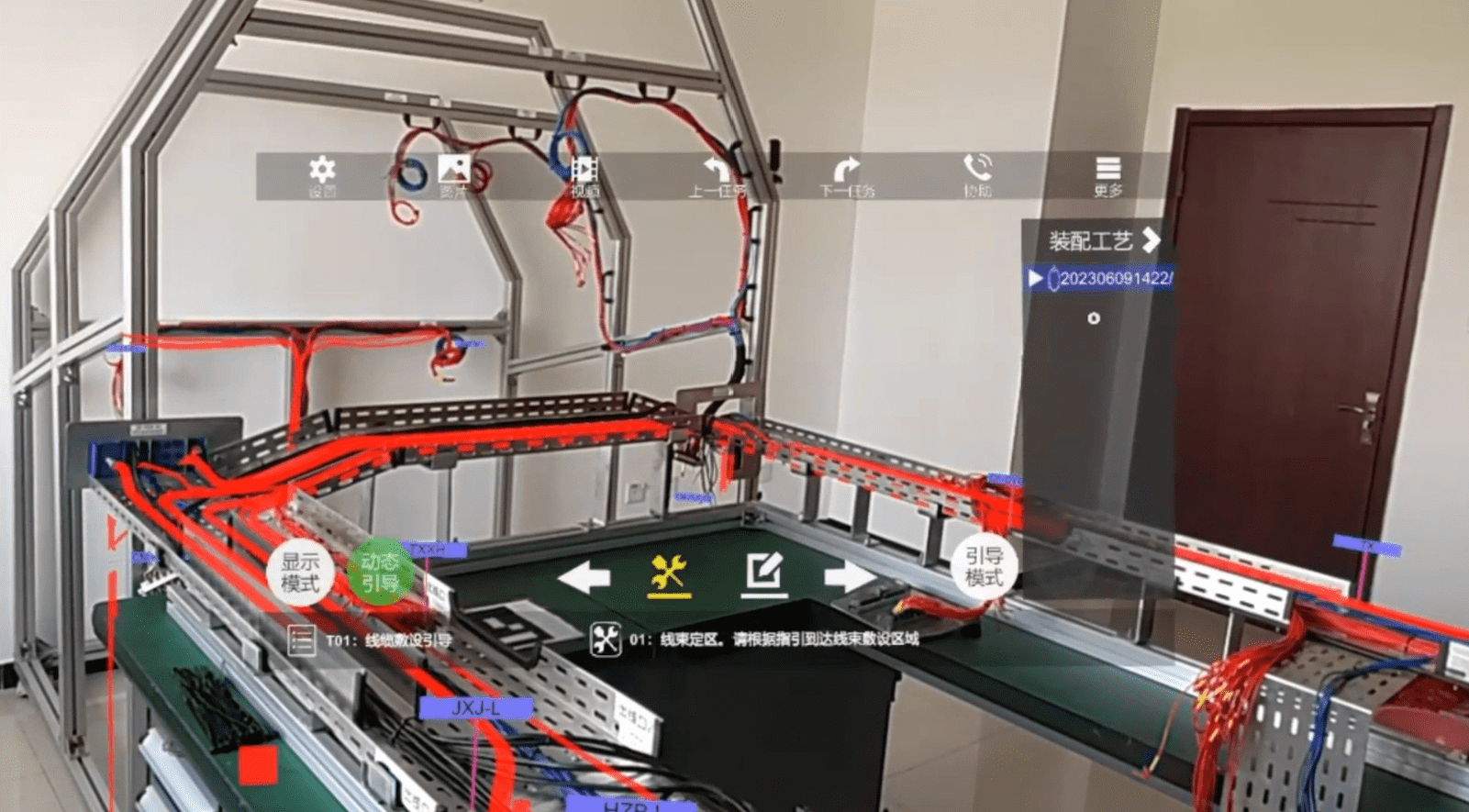

Intelligent Laying Guidance and Inspection of Cross-scale Complex Wire Harnesses

Multi-scale scenes exhibit characteristics such as texture deficiency and limited local field of view, which pose challenges for achieving high-quality registration and occlusion handling in large-scale cable laying scene models using AR technology. To address these challenges, our project team has developed an innovative marking-free AR guidance system for large-scale cable laying operations, significantly enhancing the intelligence level of the process. The system enables operators to wear smart glasses and initiate automatic pose estimation and model registration through intuitive gesture interactions, then perform step-by-step cable laying operations under real-time AR guidance. This novel approach demonstrates a significant improvement in efficiency, achieving a 27.21% increase compared to traditional wire table-based methods.

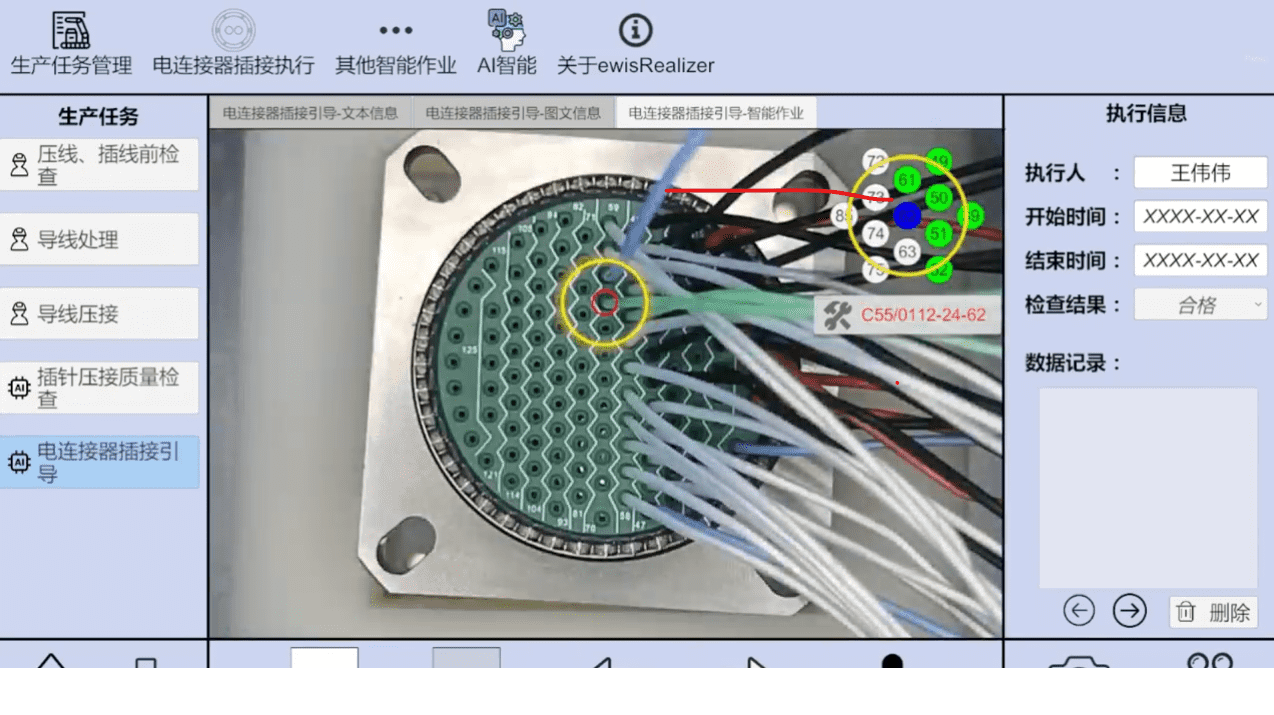

Intelligent Insertion and Precise Guidance of Micro High-density Electrical Connectors

The insertion of micro high-density electrical connectors presents significant challenges due to their tiny pin diameters, closely spaced contacts, lack of numbering, and tendency to be obscured by wires. Manual insertion requires magnification, which not only reduces efficiency but is also prone to human error. This innovative technology introduces an intelligent precision insertion guidance method that combines several advanced techniques: automatic generation of prior knowledge from 3D models, hole positioning using deep learning and 3D tracking, hole position completion and sorting via point set registration, and human-machine collaboration guidance based on obstruction levels. Testing has demonstrated exceptional performance: the automatic generation of prior knowledge achieves a precision of 0.047 mm and a 99.97% improvement in efficiency, meeting all usability criteria. The system's ability to identify and locate physical holes achieves a positioning accuracy of 0.15 mm, fulfilling precision requirements. Additionally, the guidance system adapts to varying levels of obstruction throughout the entire insertion process, dynamically adjusting its strategy as needed. This method significantly enhances both efficiency and reliability, providing precise guidance for the entire insertion process of micro high-density electrical connectors.

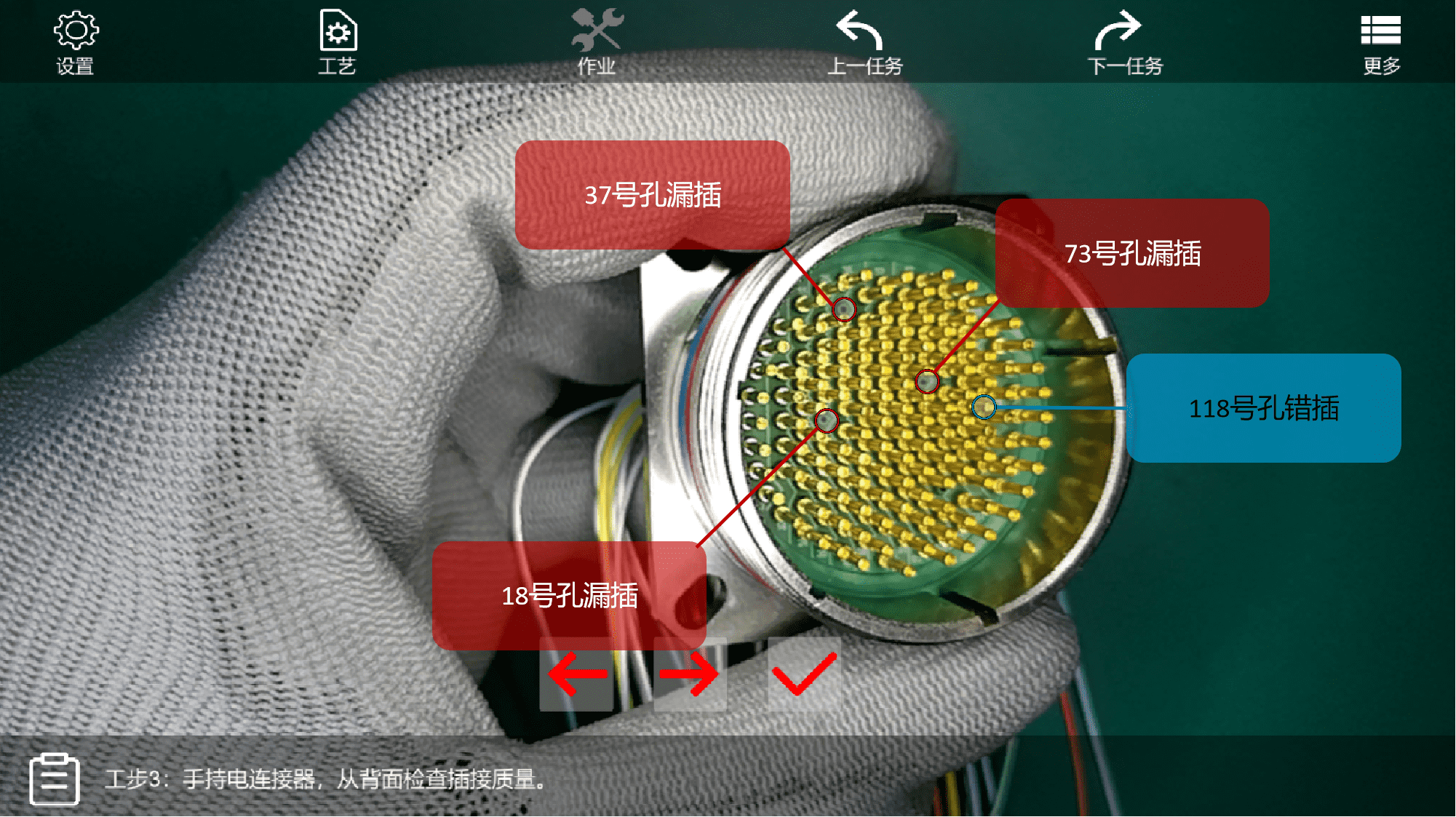

Human-machine Collaborative Intelligent Detection of Insertion Quality for Aviation Electrical Connectors

Aviation electrical connectors are critical components whose misalignment during installation can lead to degraded performance or even system failures. Traditional inspection methods, which rely on manual visual checks and paper-based process documents, are inherently inefficient and prone to human error. This innovative solution introduces a human-machine collaborative intelligent detection system that enhances reliability and efficiency. The system employs a two-stage detection process: first, utilizing color-based features for initial pin localization, followed by secondary positioning and sequence verification using predefined knowledge and process data to ensure accurate quality control. In cases where connector orientation significantly impacts recognition accuracy, the system automatically transitions to a vision-guided human-machine collaborative inspection mode. Extensive testing has demonstrated exceptional performance, achieving 100% pin recognition accuracy under normal viewing conditions and maintaining high reliability through adaptive inspection strategies in complex orientations. This advanced detection method not only significantly improves operational efficiency and accuracy but also ensures consistent high-quality assembly of aviation electrical connectors.

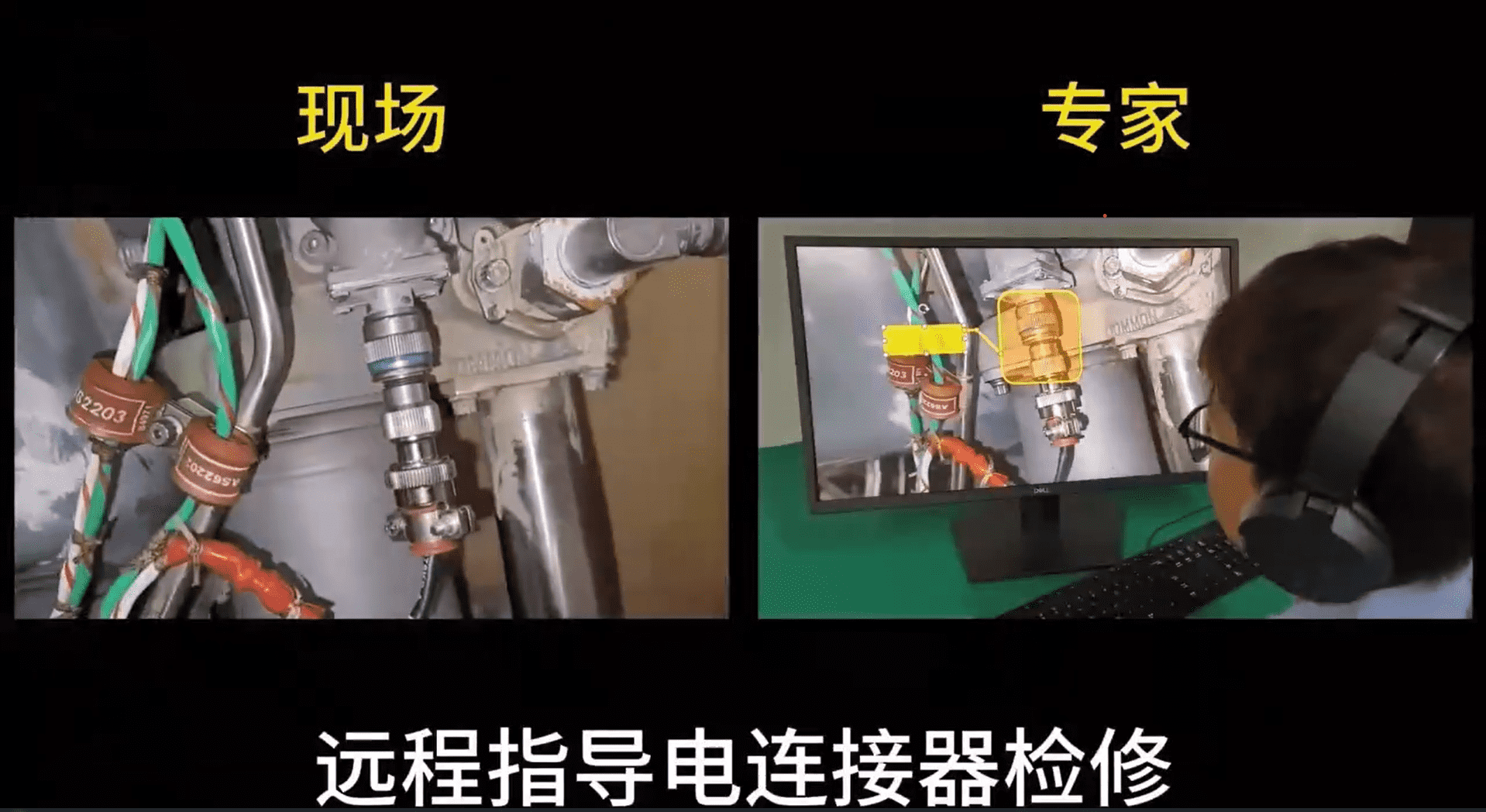

Intelligent Remote On-site Assistance for Operation and Maintenance Support of Complex Equipment

In the operation and maintenance of complex equipment, on-site issues often involve complex, multidisciplinary challenges. Traditional approaches that rely on dispatching experts to the site are not only time-consuming and costly but also result in suboptimal emergency response efficiency. To address these limitations, this innovative technology introduces a novel intelligent remote assistance method. By integrating state-of-the-art technologies such as multimodal perception, voice and visual interaction, and augmented reality overlay, this system enables real-time transmission of the on-site operating environment to remote expert terminals. This creates an immersive guidance experience for operators, significantly improving the maintenance process. The system employs advanced algorithms to intelligently identify critical components and operational procedures. By leveraging a comprehensive process knowledge base, it generates clear, step-by-step visual guidance. Furthermore, the system supports intuitive voice commands and gesture-based interactions, ensuring a seamless and efficient workflow. Experimental results demonstrate the remarkable effectiveness of this approach, with response times reduced by a dramatic 65.8%. This breakthrough solution not only enhances the efficiency of complex equipment maintenance but also significantly improves the reliability of the overall operation and support system.

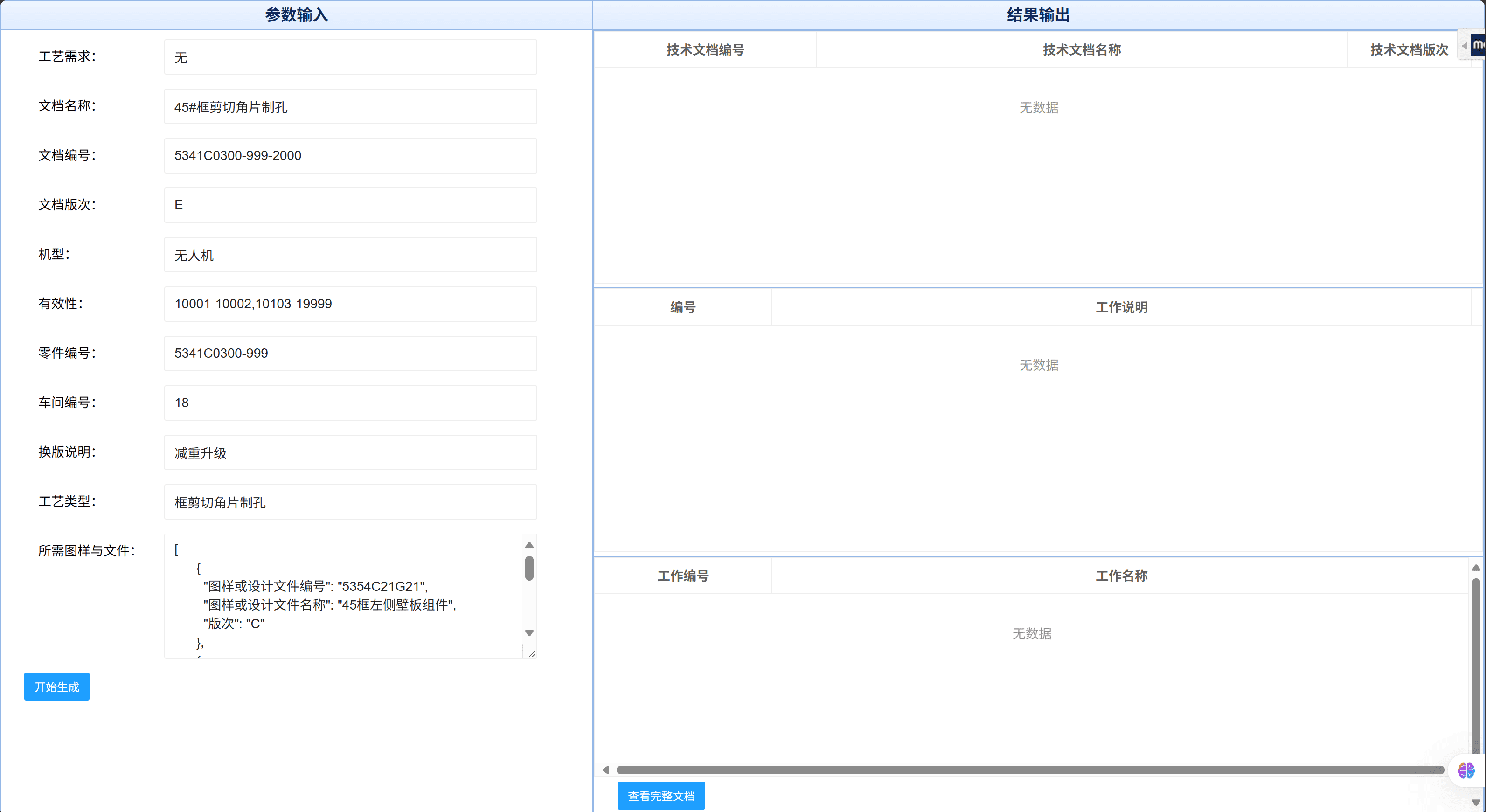

High-quality Intelligent Generation of Assembly Processes Based on Large Models

This technical study proposes an innovative, no-code intelligent generation method for Assembly Order (AO) documents based on large language models. Aimed at addressing the inherent challenges in traditional AO document creation, including complex workflows, knowledge-intensive requirements, and stringent format specifications, this method leverages cutting-edge technologies including prompt engineering, Retrieval-Augmented Generation (RAG), and structured workflow automation. The system's architecture enables automatic parsing of process requirements, precise retrieval of relevant content from domain-specific knowledge repositories, and systematic generation of compliant documentation. Key outputs include standardized work instructions, detailed process flows, and supporting technical documents. Experimental validation demonstrates exceptional performance, with document accuracy exceeding 95% and generation times reduced to 30–90 seconds per document. These improvements significantly enhance both production efficiency and documentation consistency, establishing a robust foundation for the intelligent automation of assembly process development. The approach represents a substantial advancement in AO document generation, offering a scalable and efficient solution to longstanding challenges in the field. By integrating these advanced technologies, the method provides a practical pathway toward fully automated, high-quality assembly process documentation.

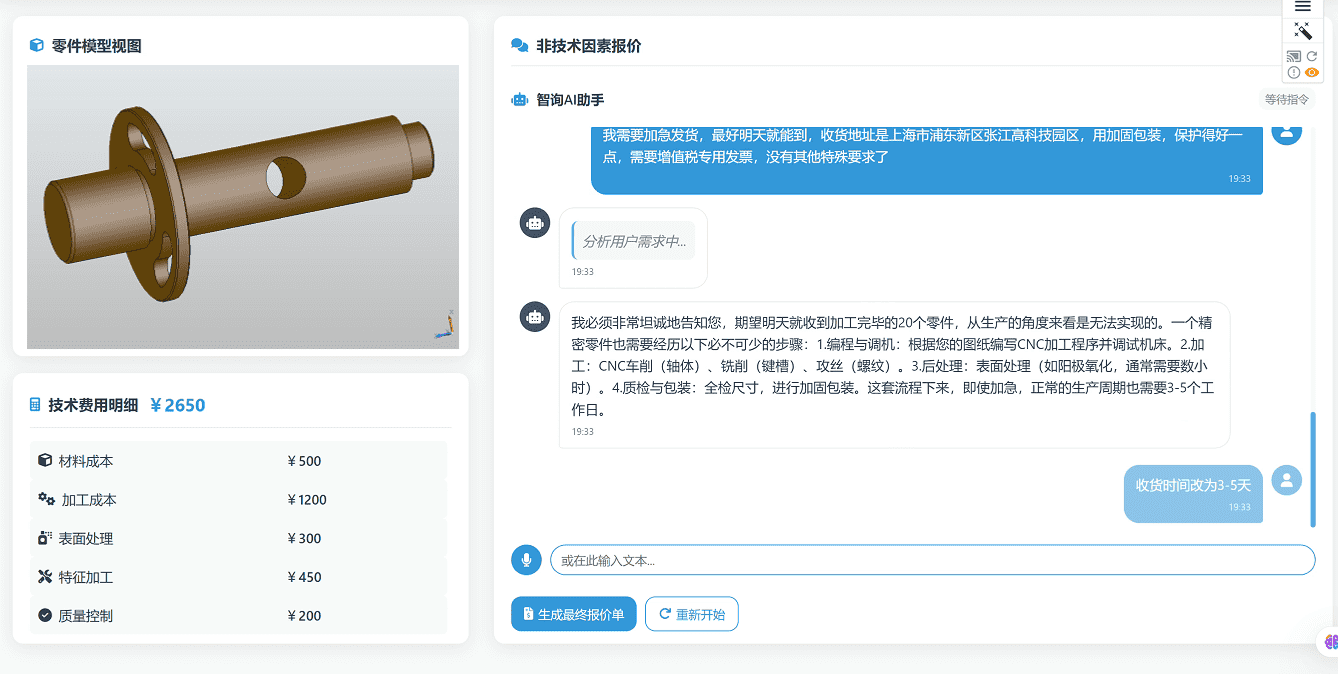

Intelligent and Precise Evaluation of Part Processing Cost Based on Large Models

Targeting the challenges faced by small and medium-sized enterprises (SMEs) in the traditional quotation process, including manual-intensive operations, lengthy cycles, and high technical barriers, we present an innovative intelligent quotation evaluation system for parts processing. This system leverages cutting-edge large language models (LLMs) with advanced lightweight 3D feature recognition technology to deliver a fully automated, end-to-end quotation solution. By simply uploading part models and articulating requirements, users receive detailed, interpretable quotations within minutes. Our solution aims to democratize intelligent manufacturing solutions, empowering SMEs to optimize operational efficiency, reduce costs, and advance toward a new era of digital ecosystem integration and industrial collaboration.

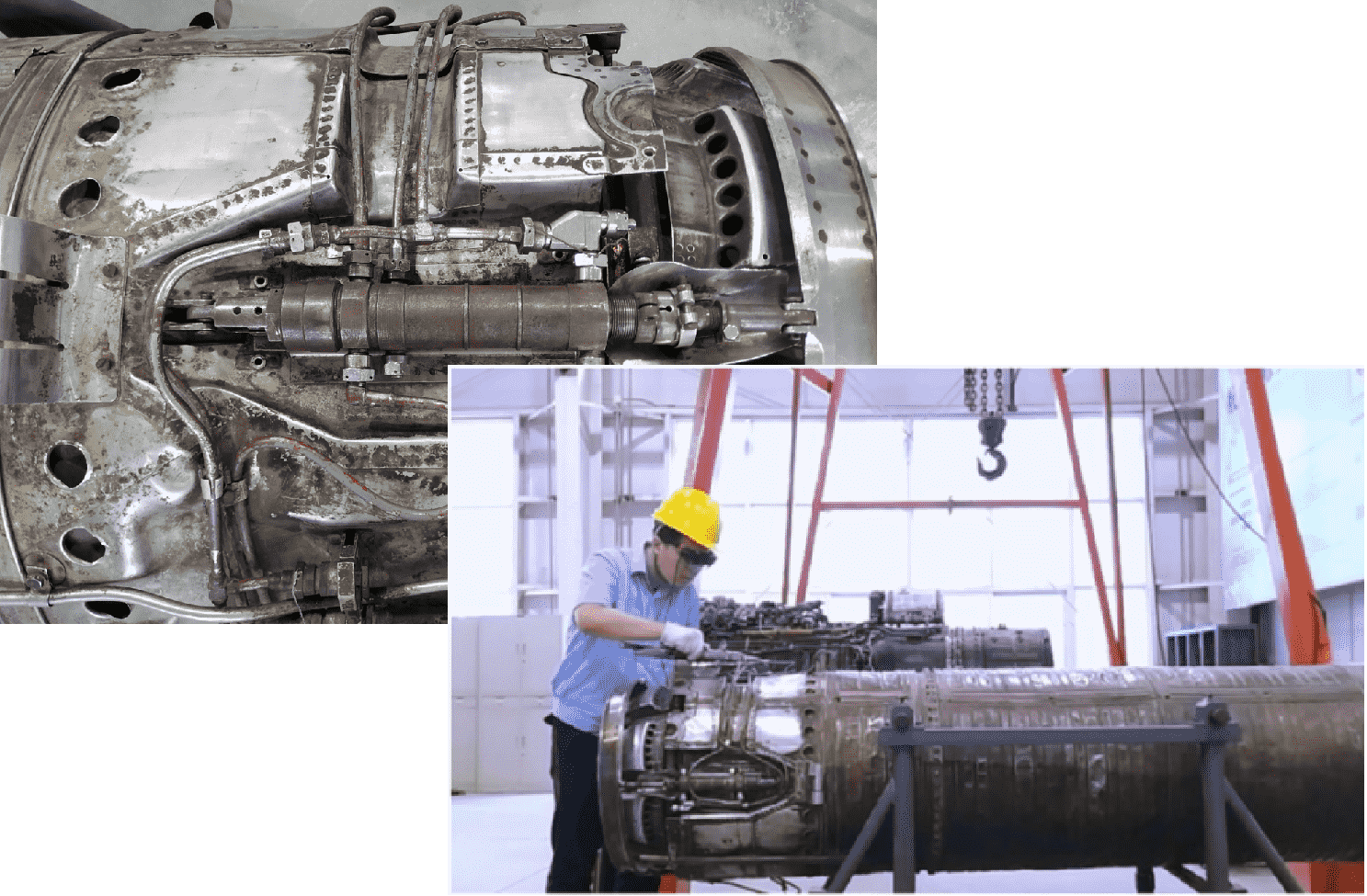

Intelligent Maintenance of Aeroengine Actuators

The actuator, a critical component of aeronautical engines, directly influences an aircraft's maneuverability, takeoff, and landing performance by modifying the tail nozzle's cross-sectional area. Maintenance of this essential component entails intricate disassembly and reassembly operations involving both the engine structure and the actuator itself, rendering the process lengthy and technically demanding. In the context of aeroengine actuator servicing, the integration of smart glasses augmented with the OpenIAI application offers significant advantages. Maintenance personnel benefit from real-time guidance, enabling precise identification of component positioning, adherence to standardized maintenance protocols, and continuous quality assurance throughout the repair process. This advanced technological support not only enhances operational efficiency but also elevates the overall quality of actuator maintenance procedures. Furthermore, the application of such intelligent tools ensures consistency and precision in every stage of the repair workflow, thereby contributing to improved maintenance outcomes and operational reliability.

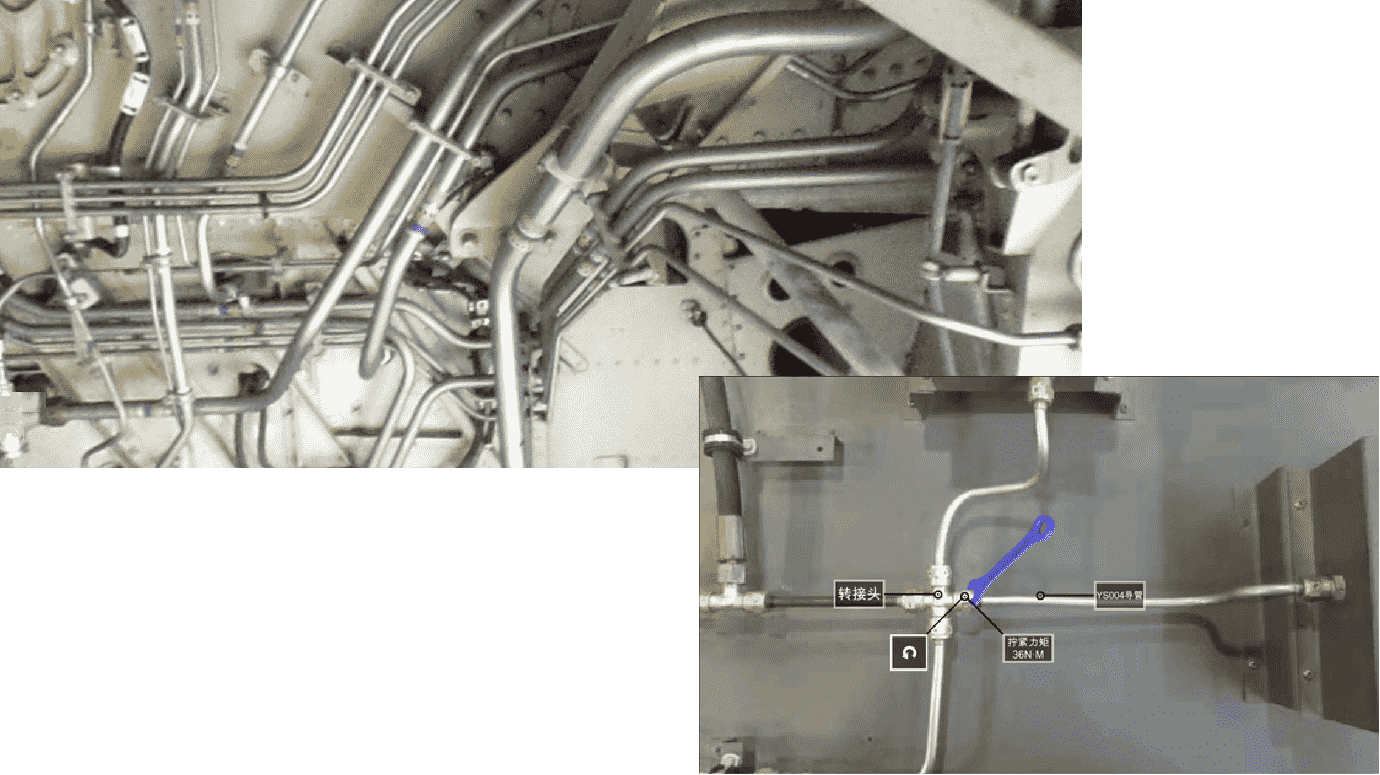

Intelligent Assembly of Aircraft Hydraulic Pipelines

The aircraft hydraulic tubing system serves as the primary transmission pathway for hydraulic power, acting as the "lifeline" of the aircraft. The quality of its assembly directly impacts the aircraft's safety performance. However, due to the intricate structure, numerous components, and confined spaces involved, the assembly process is highly complex and labor-intensive, often becoming a bottleneck in the aircraft manufacturing sequence. The OpenIAI system leverages deep learning technology to accurately identify and inspect complex irregular-shaped tubing components. By integrating with the actual assembly environment, it offers real-time intelligent guidance, enabling operators to perform "see-and-assemble" operations. The system also employs intelligent assessment to verify assembly accuracy, thereby enhancing the standardization and precision of tubing installations. This advanced solution empowers aircraft assembly personnel to achieve efficient and high-quality on-site assembly results.

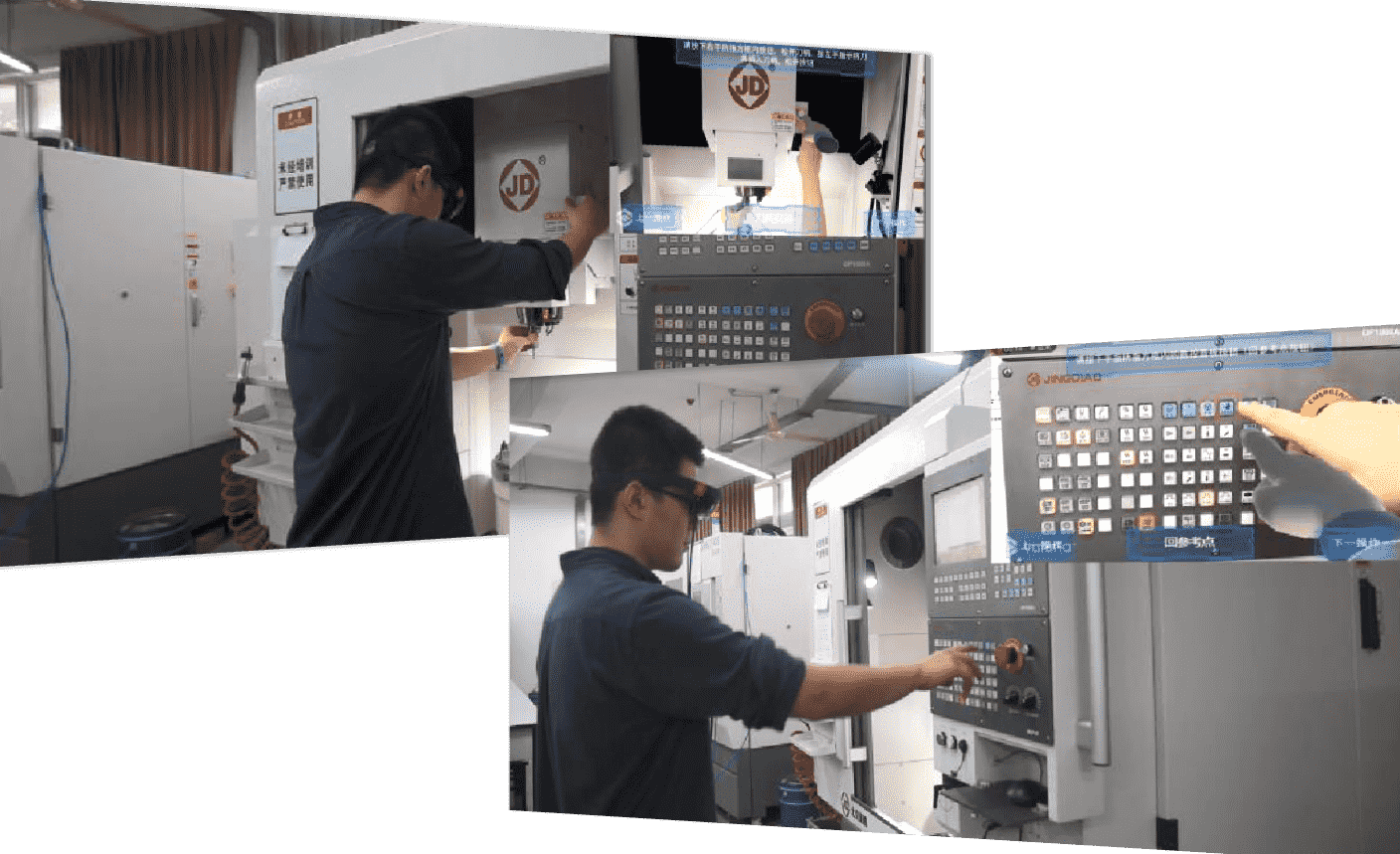

Intelligent Training for Precision CNC Machine Tool Operation

Precision CNC machine tools serve as the primary processing equipment for the high-end equipment manufacturing sector, characterized by their complex operational procedures, high spindle speed, and strong real-time performance requirements. Training on such machinery presents notable safety risks and involves significant training expenses. The OpenIAI system provides intelligent guidance throughout the CNC machining training process, assisting trainees in accurately completing workholding setup, tooling configuration, part alignment, and CNC system operation. This ensures a safe training environment, enhances skill acquisition efficiency and proficiency levels, and effectively reduces overall training costs.

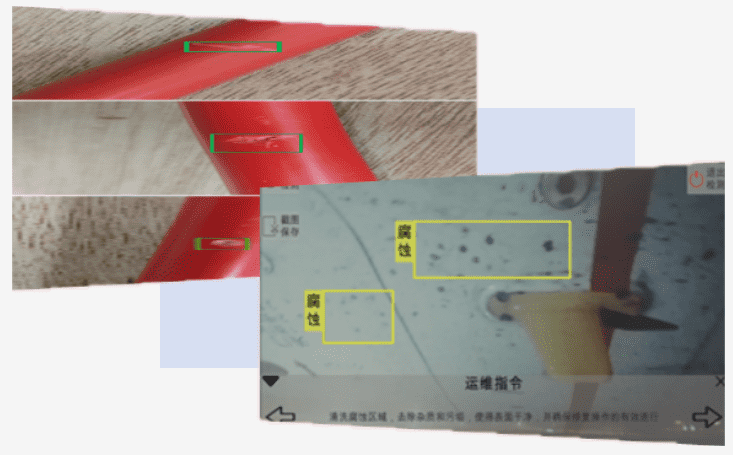

Intelligent Inspection of Surface Defects on Aircraft and Cables

Surface inspection of aircraft and cables is a critical process to ensure aviation safety and equipment reliability. Defects on aircraft surfaces, such as cracks, corrosion, or wear, can lead to a reduction in structural integrity, thereby increasing flight safety risks. Similarly, wear, aging, or damage on the surface of cables may lead to electrical failures, which can disrupt the normal operation of aircraft systems. Traditional manual visual inspections, while widely used, are susceptible to human error and oversight, particularly influenced by factors such as inspector experience and environmental conditions. The OpenIAI system addresses these challenges through advanced deep learning and image processing technologies, enabling automated detection and analysis of surface defects on both aircraft and cables. By utilizing historical defect image data from real-world scenarios, the system employs sophisticated image augmentation techniques to enhance the defect dataset, ensuring robust model training. Furthermore, the integration o f augmented reality technology within the OpenIAI system revolutionizes the inspection process, providing real-time feedback and visualization. This innovative approach significantly improves the accuracy and efficiency of inspections, ultimately contributing to enhanced aviation safety and operational reliability.